The gyratory cone crusher is the tertiary crusher in the crushing sequence. It crushes secondary crushed and retained material from a 25mm screen of approximate size 45mm – 25mm through the use of an eccentric rotation. The rotation occurs only at the bottom of the main shaft. A 150KW electric motor creates the drive to the eccentric assembly through multiple drive V belts.

The Omnicone is different; however still a gyratory crusher, to the Jaques gyratory cone crusher.The Omnicone main shaft assembly is not supported at the top its shaft. The main shaft is driven and supported through the eccentric assembly. The eccentric assembly turns at a constant speed, causing the entire main shaft to gyrate. The process is continuous.

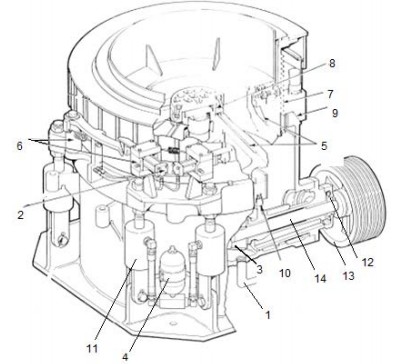

Gyratory cone crusher principles apply to the Omnicone; see 900mm Jaques

gyratory cone crusher

1 Oil return line

1 Oil return line

2 Adjustment cylinders

3 Pinion and crown wheel gears

4 Tramp cylinder accumulators

5 Mantle and concave wear liners

6 Concave adjustment locking mechanism

7 Adjustment thread

8 Head nut cover

9 Top shell locking surface

10 Dust seal

11 Tramp cylinders

12 Pinion seal

13 Multi V belt pulley

14 Pinion shaft

As a tertiary crusher, the Omnicone uses a tertiary mantle and concave which uses a more blunt profile mantle and concave than a secondary crusher mantle and concave wear liner shape profile. The tertiary mantle and concave shape limits the input size of material. As a tertiary crusher it also operates with a CSS of approximately 15 – 18mm. Due to the tighter CSS and the tertiary profile the material thro put, that amount of processed material is lower than the secondary crusher.

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;