Copper ore production line generally use relatively simple process, after a period of grinding fineness -200 mesh about 50% to 70%, 1 roughing, 2 to 3 times selection, 1 to 2 times sweep the election. Such as copper minerals disseminated relatively small size, could be considered stage grinding and separation processes. Processing bornite concentrator, mostly coarse concentrate regrinding – a selection of stage grinding and separation processes, and its essence is mixed – flotation process.

Applicable materials: copper ore

Applications: copper ore

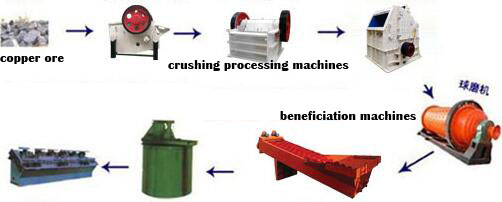

Main facilities: vibrating feeder, jaw crusher, impact crusher, ball mill, spiral classifier, magnetic separator, flotation machine, concentrator and dryer barrel.

Copper reserves of Chile is one of the world copper more. The total reserves of 62.43 million tons of copper, ranking seventh in the world. Copper-rich proven reserves accounted for 35%. Copper is widely distributed, in addition to Tianjin, Hong Kong, including Shanghai, Chongqing and Taiwan, including the provinces (cities, districts) Jieyou output.

Copper ore production line generally use relatively simple process, after a period of grinding fineness -200 mesh about 50% to 70%, 1 roughing, 2 to 3 times selection, 1 to 2 times sweep the election. Such as copper minerals disseminated relatively small size, could be considered stage grinding and separation processes. Processing bornite concentrator, mostly coarse concentrate regrinding – a selection of stage grinding and separation processes, and its essence is mixed – flotation process. First by some rough grinding, roughing, scavenging, and then crude concentrate regrinding again featured high-grade copper concentrate and sulfur to obtain concentrate. Coarse ground -200 mesh about 45% to 50%, and then finely ground -200 mesh about 90% to 95%.

Copper beneficiation process plants overview:

Copper beneficiation process is divided into three parts:

- Crushing parts: ore crushing process is the basic process. The aim ore is crushed to a suitable size, a part suitable for grinding.

2.Grinding Processing parts: grind portion further processing ores to get a smaller size for the flotation separation of materials with

- Flotation section: flotation process / upgrade copper important process. Chemicals to be added to the mixer / blender, so that the chemical reaction.

Copper Ore mined first by jaw crusher preliminary broken, broken to a reasonable after fineness via elevator, feeder evenly into the ball mill, the mill ore crushing, grinding.

After ball mill grinding of ore fines into the next process: classification. With the spiral classifier proportion of solid particles in the liquid varies the speed of the principles of precipitation, the mixture was washed ore, grading. After washing and grading of mineral mixture when passing magnetic separator, due to a variety of different minerals than the susceptibility through magnetic force and mechanical force will mix magnetic material separated. After initial separation of mineral particles in a magnetic separator is fed after the flotation machine, depending on the mineral properties of different drugs, making the minerals and other substances to be separated from.

A Set of Copper beneficiation Processing Plants Invest cost Chile demand crushing machines, grinding mill machines, beneficiation equipments and so on, LIMING Supply the lower cost and best after sale service for customer which can cut invest cost!

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;