Cone crusher is suitable for metallurgy, construction, road building, chemical and silicate industry, and can crush medium and above hardness ores and rocks. Cone crusher is often working in onerous conditions environment, so the oil lubrication system should maintain smooth.

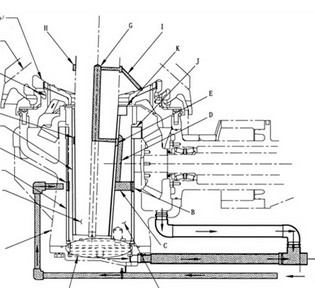

Lubrication method of cone crusher lubrication systems

1. Cone crusher uses the grease should be based on use of regions, climate conditions, usually using calcium based, sodium based or calcium base grease. When a drier in grease, thin oil and grease are available use after reconciling.

2. Between cone crusher toggle plate and toggle plate pad only when the assembly or maintenance, in the land with the right amount of grease.

3. To ensure the normal operation and extend the service life of the cone crusher should be grease lubricated regularly. (typically once every 3-5 days plus).

4. It should be added in the bearing lubricating greases as of volume-50%, every 3-6 months change again. Changing the grease application with clean gasoline or kerosene careful cleaning roller bearing parts, it should open the housing of the drain hole during cleaning.

Cone crusher lubrication system maintenance is important, and it can ensure their normal operation. A good lubrication system is an effective way to reduce friction but also to extend the life of cone crusher.

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;