Basalt quarry Quality control

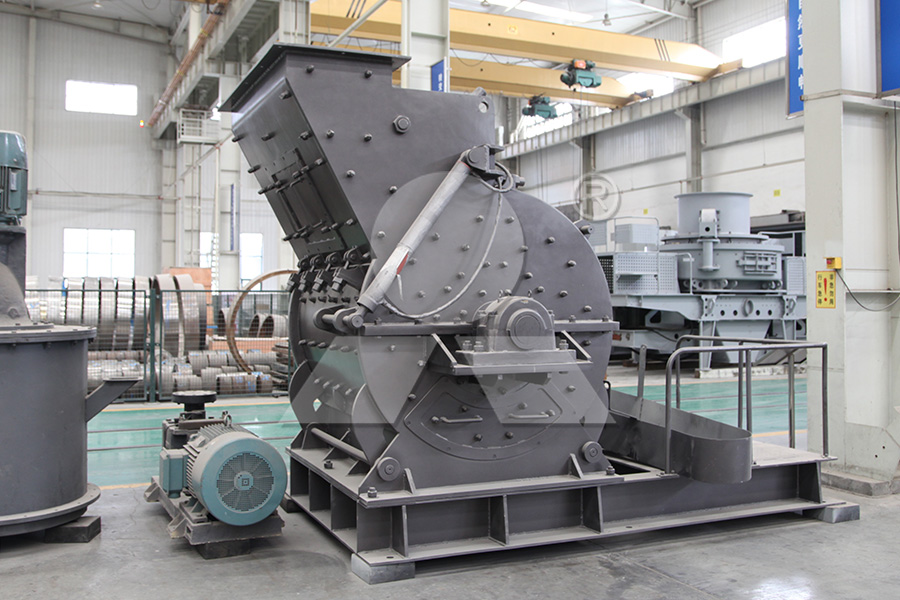

When it comes to producing high-quality basalt CM coarse powder crusher, the quality of the raw material is crucial. This is where quarry quality control comes into play.

Basalt quarries are carefully selected and inspected before mining operations begin. The quality of the basalt rocks in a quarry determines its suitability for use as construction materials.

Basalt quarry Quality control

During extraction, samples are taken at various stages of production to ensure that the final product meets certain standards set by industry regulators. These include testing for particle size distribution, chemical composition, and physical properties like hardness and abrasiveness.

To maintain consistency in their products’ physical characteristics, most manufacturers employ stringent process controls backed by advanced laboratory equipment. They also have skilled personnel who conduct regular tests on samples from different batches to identify any variations early enough before they affect production or product performance.

Strict quarry quality control ensures that customers receive basalt CM coarse powder crushers that meet their expectations regarding strength, durability, and reliability – all key factors when considering cost savings over time due to less maintenance needed on machinery used with these materials.

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;