Introduction to Graphite Mining machines

Welcome to the world of graphite mining machines, where cutting-edge technology meets the unstoppable demand for this extraordinary mineral. In today’s blog post, we will explore the fascinating realm of graphite crushing and screening equipment – a crucial process in extracting and refining this invaluable resource.

Graphite, renowned for its exceptional properties such as high thermal conductivity and lubricity, has become an indispensable ingredient in various industries. From aerospace to electronics, from energy storage to automotive applications – graphite plays a pivotal role in shaping our modern world.

Graphite crushing and screening equipment sales price

But before we delve deeper into the intricacies of graphite crushing and screening machines, let’s first understand why investing in these technologies is not just essential but also cost-effective. So buckle up and join us on this exciting journey through the world of graphite mining!

The Crushing and Screening Process invest cost

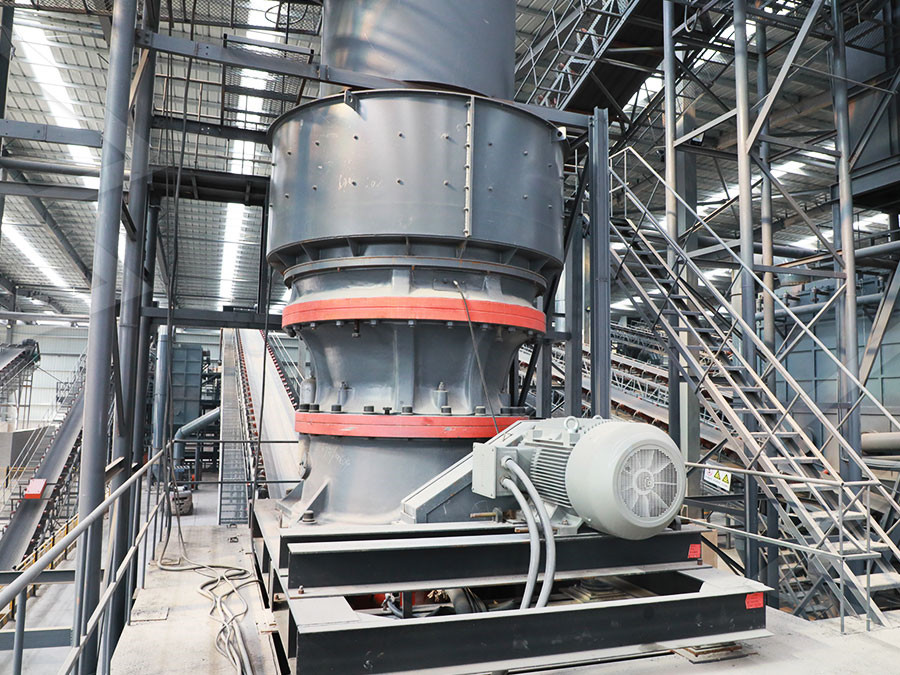

The crushing and screening process is a crucial step in the graphite mining industry. It involves breaking down large chunks of graphite into smaller, more manageable pieces that can be further processed. This process requires specialized equipment that is designed to handle the unique properties of graphite.

When considering the investment cost of crushing and screening equipment, there are several factors to take into account. First and foremost is the initial purchase price of the machines themselves. Different manufacturers offer varying prices for their equipment, so it’s important to do your research and compare options.

Another factor to consider is the ongoing maintenance and operating costs associated with the equipment. This includes things like fuel consumption, electricity usage, and regular maintenance checks. These costs can add up over time, so it’s important to factor them into your overall budget.

Additionally, you should also consider any additional features or technology that may be included with the equipment. Some machines may have advanced automation capabilities or innovative design features that could improve efficiency and productivity.

Investing in high-quality crushing and screening equipment for graphite mining operations can yield significant returns in terms of increased production capacity and improved product quality. However, it’s essential to carefully evaluate all aspects of cost before making a decision on which equipment best suits your needs.

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;