Flue gas desulfurization is the most effective and main technology in the large-scale controlling acid rain. At present, wet desulfurization process technology becomes the most popular in the worldwide power industry, and achieves 85%. Limestone gypsum wet technology has the features of low cost, high efficiency, and has become the most widely used power plant flue gas desulfurization process.

In order to response the environmental requirements, Liming imported national advanced grinding technology, and launched Super Pressure Trapezium Mill series, which is the world’s most advanced blast furnace desulfurization grinding system in power plant and steel mill. This desulfurization Mill is the new and large patent desulfurization grinding equipment.

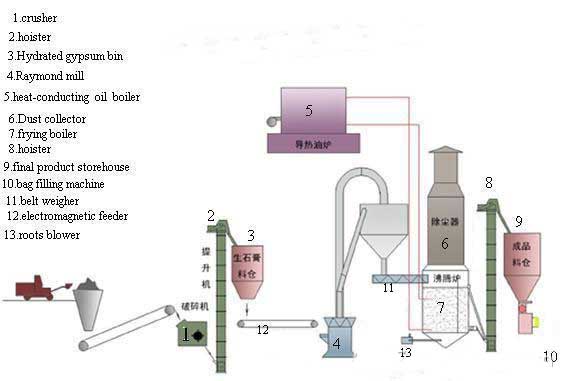

The desulfurization gypsum production line is especially suitable for large-scale thermal power plant desulfurization and steel mill desulfurization and mainly includes High Pressure Suspension Mill, Micro Powder Mill, Super Pressure Trapezium Mill, vibrating feeder, fine jaw crusher etc.

Desulfurization mill has the features of high yield, low energy consumption, environmental protection, easy maintenance etc. In addition, according to different calcium content, the design process of desulfurization mill is also different. According to different technical requirements, it can adjust the particle size and fineness of finished product.

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;