Raymond mill designed by adopting German advanced milling technology, combining the characteristics of similar domestic products. So, it is getting perfect by low consumption, low investment, environment friendly, small occupation area, and more efficient than the traditional raymond mill.

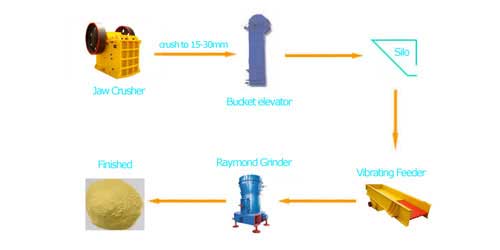

Raymond mill machine flow chart

Firstly, raw material is crushed by jaw crusher to the size required, and then the crushed materials are elevated into a hopper from which the material is transported through the electro-magnetic vibrating feeder evenly and continuously into the grinding chamber for powder-processing. The rollers of raymond mill oscillate outward to press the ring because of the centrifugal force and the shovel scoops up the materials, send to the middle between ring and roller to accomplish the grind. After this, the ground stuff is carried by the air from the blower into the separator for screening. The fine powers are blow into the cyclone collector and are poured out through the output-powder valve as the final products and the rough stuff after the screening will be recycled back into the grinding chamber for regrinding. The airflow system is closely sealed up and circulated under condition of negative and positive pressure.

We are a professional and famous raymond mill manufactures, and supply various models raymond mill machines. Our products are all adopting national advanced technology, and exported to many countries, such as Pakistan, Sri Lanka, Bangladesh, Indonesia, Philippines, Malaysia, Vietnam, Singapore, Turkey, Israel, Burma, Jordan, Yemen, Iran, Iraq, Afghanistan, Syria, Kuwait, Kazakhstan etc.

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;