The mining process of basalt

The mining process of basalt is a fascinating and intricate operation that involves several stages. It all begins with the identification of suitable basalt deposits through extensive exploration and geological surveys. Once a viable deposit is identified, the next step is to obtain the necessary permits and licenses for mining operations.

Basalt mining typically involves the use of heavy machinery such as excavators, bulldozers, and crushers to extract the basalt from its natural state. The first step in this process is drilling holes into the rock face to insert explosives. These explosives are then detonated to break up the solid rock into manageable pieces.

The mining process of basalt

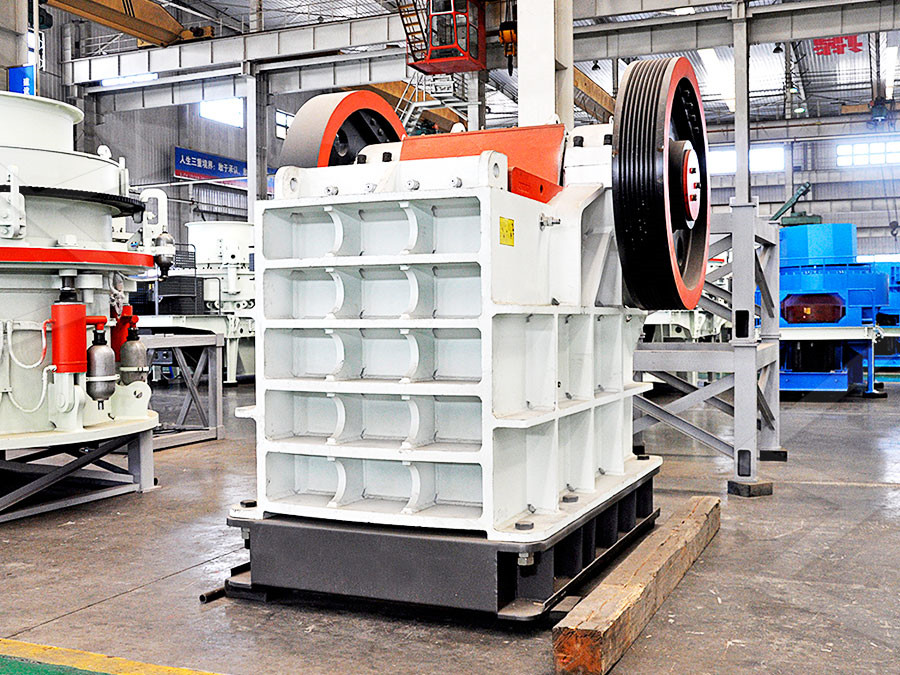

After blasting, loaders or trucks are used to transport the broken rocks to a crushing plant where they are further processed. Here, large jaw crushers or gyratory crushers reduce the size of the rocks even further. The crushed basalt can then be sorted into different sizes depending on its intended use.

It’s important to note that sustainable mining practices are essential during this process to minimize environmental impact and preserve natural resources. This includes proper waste management, reclamation efforts, and adherence to safety regulations.

The mining process of basalt requires careful planning, skilled labor, and efficient machinery. By following these steps diligently, we can ensure a steady supply of high-quality basalt for various construction projects while minimizing any negative effects on our environment

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;