The Process of Producing High-Quality Construction Aggregate

The process of producing high-quality construction aggregate is a meticulous and precise endeavor. It involves several key steps that ensure the final product meets the required standards.

Raw materials are carefully selected and sourced from various quarries based on their quality and suitability for the desired end product. These materials may include crushed stone, sand, gravel, or even recycled concrete.

The Process of Producing High-Quality Construction Aggregate

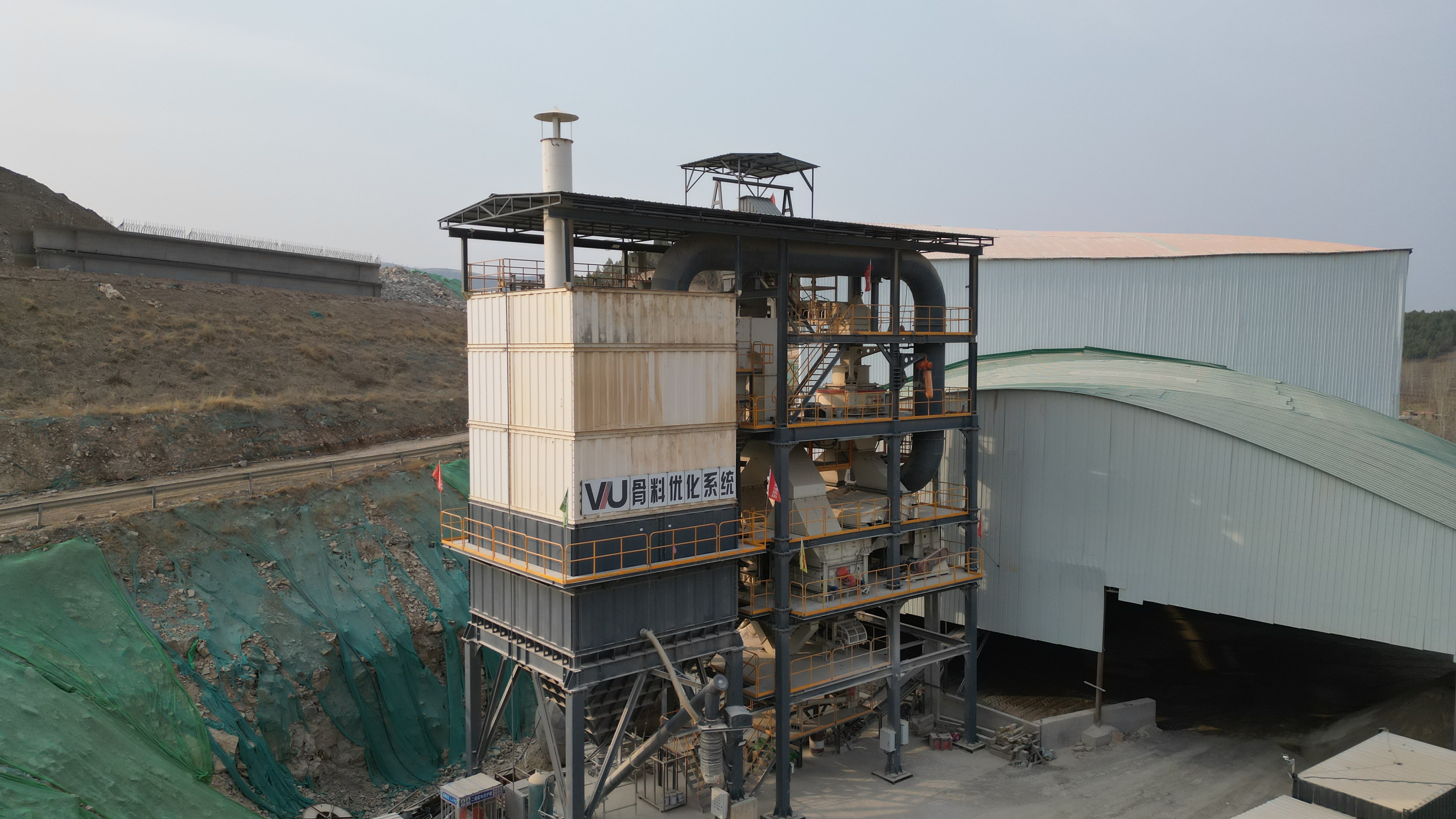

Once the raw materials have been collected, they undergo a series of crushing and screening processes to break them down into smaller sizes. This ensures uniformity in particle size distribution and removes any impurities present.

Next, these crushed materials are mixed together in specific proportions to create a well-graded blend. This blend is then further processed through methods like washing or scrubbing to remove excess fines or undesirable particles.

Afterwards, this mixture goes through additional stages such as shaping and grading to achieve the desired characteristics for use in construction applications. Special attention is given to ensuring that the aggregate has good angularity, durability, and resistance to wear.

Rigorous quality control measures are implemented throughout the production process to monitor parameters such as gradation, moisture content, and particle shape. Any deviations from specified standards are promptly addressed to maintain consistency in output quality.

Producing high-quality construction aggregate requires careful selection of raw materials followed by systematic processing methods combined with strict quality control measures at every stage. The result is an exceptional product that meets industry requirements while ensuring optimal performance in various construction projects!

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;