Introduction to Dolomite Cone Crusher

Welcome to our blog post on the fascinating world of dolomite cone crushers! If you’re curious about how these powerful machines work and what sets them apart from other types of cone crushers, you’ve come to the right place. In this article, we’ll delve into the working principle of HPT (High Performance Technology) dolomite cone crusher, uncovering its advantages, features, maintenance tips, and common applications. So buckle up and get ready for a deep dive into the exciting realm of dolomite cone crushers!

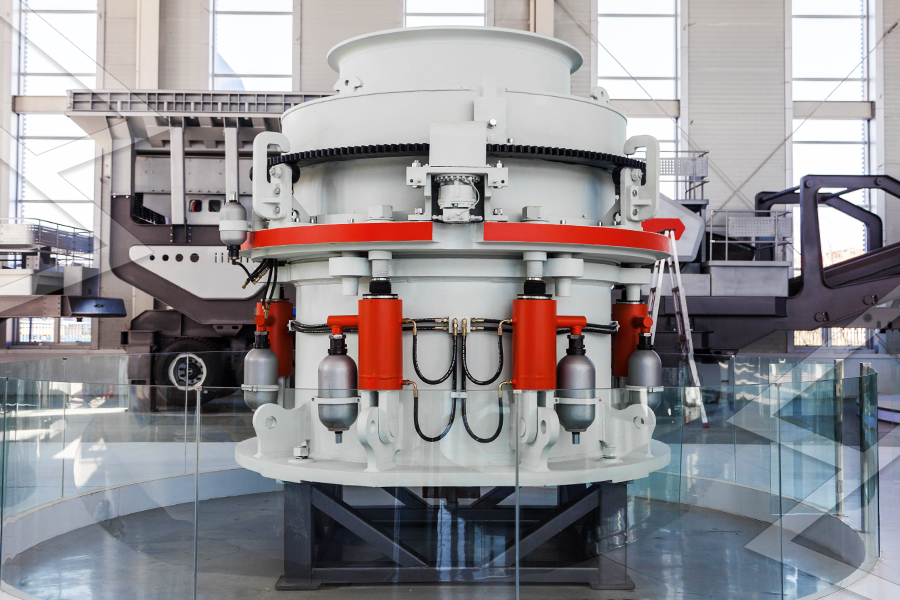

How Does a HPT Cone Crusher Work?

How Does a HPT Cone Crusher Work?

The working principle of a HPT cone crusher is based on the laminating crushing process. Raw materials are fed into the crushing chamber through the vibrating feeder, and they get crushed between mantle and concave. The powerful motor drives the eccentric shaft to rotate continuously, which in turn causes the mantle to move back and forth.

Working principle of dolomite cone crusher hpt

As the raw materials pass through the crushing chamber, they are compressed between two surfaces – mantle and concave. This squeezing action results in finer particles size reduction. The crushed material then falls down through the discharge opening at the bottom of the crusher.

One key feature of a HPT cone crusher is its hydraulic system that ensures efficient operation by adjusting the discharge setting and protecting against overload. This system also helps in clearing any unwanted material that may cause blockages.

Furthermore, HPT cone crushers have an advanced control system that allows for easy adjustment of settings according to specific requirements. It provides precise regulation over final product size distribution, ensuring high-quality output.

A HPT cone crusher offers reliable performance with low operating costs due to its energy-efficient design and optimized wear parts. Its versatility makes it suitable for various applications across different industries like mining, construction, and recycling.

Innovations in dolomite cone crushers continue to be made as manufacturers strive to improve efficiency while reducing environmental impact. With advancements in technology such as automation systems and improved sealing mechanisms, future developments will likely focus on further enhancing productivity and sustainability.

In conclusion,

A HPT cone crusher operates using a laminating crushing process where raw materials are squeezed between two surfaces resulting in fine particle size reduction.

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;