Hammer Mill is suitable for processing all kinds of rocks with compressive strength less than 320MPa. Hammer Mill sher is widely used in mining, building materials, chemical industry, metallurgy, cement, ceramic, refractory industry and so on.

Hammer Mill Features

- big crushing ratio and large capacity

- Low consumption and even granule

- simple design and compact structure

- modest investment and easy management

Hammer Mill Structure

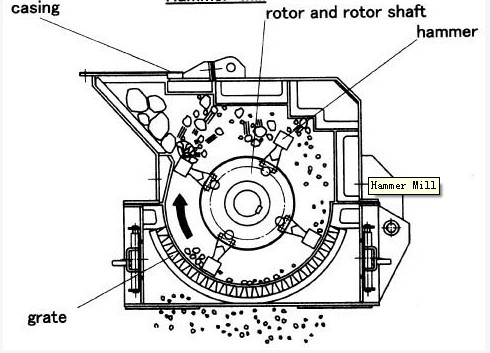

Hammer mill is consisted by the steel frame, rotor, blow bar, grizzly screen, etc. The upper part and lower part of steel frame are firmly welded, while other parts are connected by the bolts. With the high manganese steel liner which is easily changed if it is worn out, the steel frame is well protected. There are sets of hammers with exactly the same weight installed on the main shaft, and tightened by high-strength bolts.

Hammer Mill Working Principle

When it works, the motor drives the main shaft and rotors on it to rotate through V-belts. The bulk of materials will be fed into crushing cavity through inlet, and get hitten and crushed by rapidly moving hammer. Then the stone small enough to be discharged through the grizzly screen will be collected as final products, the rest would be stucked in the crushing cavity and be crushed again and again. To avoid clogging, moisture content of the material should be below 20%.

Hammer Mill Technical Data

| Name | Model | Max feed size (mm) | Handling capacity (t/h) | Power of motor (kW) | Weight (t) |

| hammer mill | PC400×300 | 30 | 5-8 | 11 | 1.5 |

| PC600×400 | 100 | 10-15 | 18.5 | 3 | |

| PC800×600 | 150 | 20-25 | 55 | 7 | |

| PC800×1000 | 280 | 20-50 | 110 | 12 | |

| Circuit Type Hammer Mill |

PCH0606 | 200 | 18-30 | 30 | 17 |

| PCH0808 | 250 | 30-50 | 45 | 29 | |

| PCH1010 | 300 | 45-80 | 90 | 52 |

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;