There is scarcity of natural sand due to heavy demand in growing construction activities which forces to find the suitable substitute. The cheapest and the easiest way of getting substitute for natural sand is by crushing natural stone to get artificial sand of desired size and grade which would be free from all impurities.

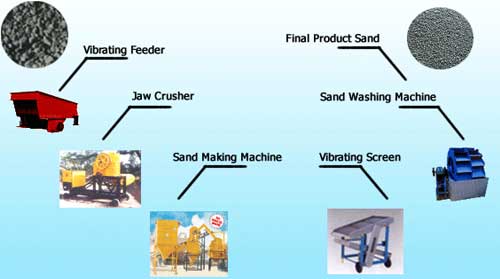

artificial sand making process flow

(Silo) -> vibrating feeder -> jaw crusher -> vibrating screen -> (finished stone), in the middle of the equipment or belt conveyor connected.

The stone material is sent regularly by the vibrating feeder to the primary jaw crusher, then it is sent to the secondary jaw crusher to be crushed again. The crushed material then is sent by belt conveyor to vibrating screen to be separated. The suitable size can be sent to the sand making machine, while unsuitable material is sent back to the secondary jaw crusher to be crushed again. The crushed material from the sand making machine is sent back to the vibrating screen to be separated. The suitable separated sand, which is the final product, should be sent to the sand washing machine to be cleaned, and then sent by the belt conveyor. The unsuitable separated sand should be sent back to the sand making machine to be crushed again. We could design different capacity’s sand production line according to your personal requests.

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;