Construction industry concrete making plants use aggregate material

With the construction industry greatly developments recently years, the concrete material has a larger demands. So aggregate making industry has greatly developments.Recycled concrete, or crushed waste concrete, is a feasible source of aggregates and an economic reality, especially where good aggregates are scarce. Conventional stone crushing equipment can be used, and new equipment has been developed to reduce noise and dust.

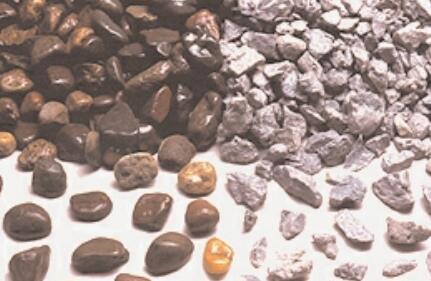

Fine aggregates (Fig. 5-1) generally consist of natural sand or crushed stone with most particles smaller than 5 mm (0.2 in.).Coarse aggregates (Fig. 5-2) consist of one or a comCHAPTER 5 Aggregates for Concrete bination of gravels or crushed stone with particles predominantly larger than 5 mm (0.2 in.) and generally between 9.5 mm and 37.5 mm (3⁄8 in. and 11⁄2 in.). Some natural aggregate deposits, called pit-run gravel, consist of gravel and sand that can be readily used in concrete after minimal processing. Natural gravel and sand are usually dug or dredged from a pit, river, lake, or seabed.

Crushed stone is produced by crushing quarry rock, boulders, cobbles, or large-size gravel. The Crushing machines including the European jaw crusher pew series, pfw impact crusher, hydraulic cone crusher and other auxiliary equipments.

Crushed air-cooled blast-furnace slag is also used as fine or coarse aggregate. The aggregates are usually washed and graded at the pit or plant. Some variation in the type, quality, cleanliness, grading, moisture content, and other properties is expected. Close to half of the coarse aggregates used in portland cement concrete in North America are gravels; most of the remainder are crushed stones.

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;