This stone crushing plant is designed to crush medium hard rock with a production capacity of 80-120 TPH, such limestone, granite, basalt, talc, etc.

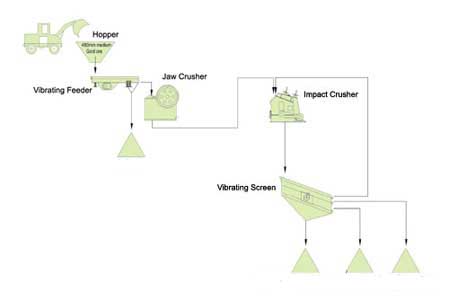

Flow chart of stone crushing plant

In our design, two stage crushing plant is the best choice, since it saves greatly the investment cost and the floor area. The crushing plant is equipped with one jaw crusher for primary crushing and one impact crusher for secondary crushing. We provide also a vibrating feeder for materials feeding and a vibrating screen of which the decks have been arranged by our engineer for products separation. Complete conveyor system channel and angle type construction is also provided for materials transport.

The following is the configuration of 80-120tph stone crushing plant

| Equipments | Model |

| 1x Vibrating Feeder | GZD1300×4900 |

| 1x Jaw Crusher | PEW-1100×1200 |

| 1x Impact Crusher | PFW1318 |

| 1x Vibrating Screen | 4YZS2460 |

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;