Wall putty is white cement & mineral based putty for use on cement concrete. Wall putty has a variety of applications and can be used on concrete, rendered walls, hollow blocks, pre-cast walls, concrete ceilings, calcium silicate bricks, aerated light-weight blocks etc.

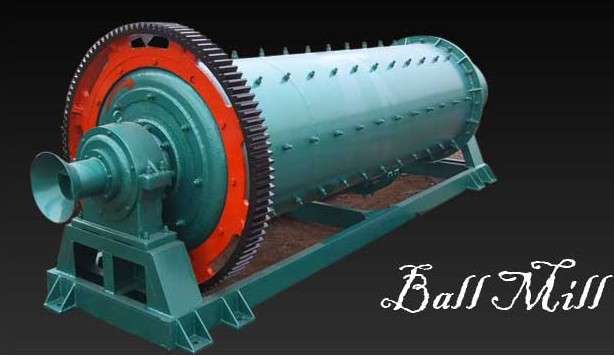

Ball mill is an efficient tool in wall putty manufacturing process in small plant. There are two ways of grinding: the dry way and the wet way. To use the ball mill, the material to be ground is loaded into the Neoprene barrel that contains grinding media. As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product into fine powder over a period of several hours.

Compared with the traditional ball mill, the matched motor power of the ball mill, which adopts this technology, can be reduced by 18% to 25% and economize 70% of the lubrication oil. The cooling water can be saved 90% and more than 20% of the comprehensive energy saving is able to be achieved.

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;