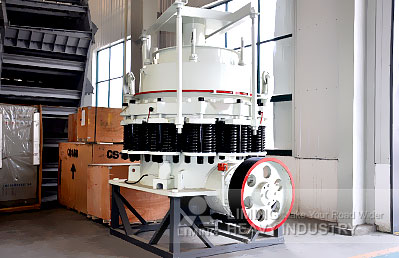

The 7′ cone crusher can crush materials with middle to very high hardness, materials such as, metal ore,granite, basalt, limestone, sandstone and much much more. If your mining or aggregate business runs 24 hours a day and needs high reduction with large capacity the cone crusher can be optimized to meet your demands.

Working principle of cone crusher

Cone crusher breaks the rocks by squeezing it between the gyrating spindles. These spindles are fully covered with resistant mantle and a manganese bowl liner covers the hopper. Rocks get squeezed at the same moment when it enters in between the bowl liner and mantle. Only one time breaking is carryout of larger pieces of rocks from ore.

Broken pieces of rocks fall down to the next position where it is broken again. Same process continues until the broken pieces become small enough so that it can pass through the narrow opening that is at the bottom of the cone crusher.

Features of cone crusher

- The crushing chamber can be setup for different materials with the finished products fineness and particle size adjustable.

- A Cone Crusher offers great productivity, superior reliability and flexibility, long service life, better final product quality.

- With reduced production costs per ton hour of material processed your operation can achieve a high level of profitability.

- Sealed and dust-proof to extend the time required between lubricant replacement and wearable parts replacement

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;