The efficient and versatile design of Liming’s Vertical Shaft Impactor (VSI) crushers deliver highly consistent end products for jobs that demand precision. Our VSI crushers are available in both stationary and portable configurations and crank out up to 640 TPH. With the capability to run in standard, semi-autogenous and fully autogenous, our models meet the most stringent material specs, allowing you to meet the challenges of any job you face.

center feeding of vertical shaft impactor(VSI)

Materials fall into the hopper and then through the feeding open in the center enter the high speed rotor which will throw out the materials with high speed. Materials firstly strike those materials that are free falling down. Then, materials strike the materials-liner in the vortex or the impact liner and are rebounded to the top of crushing chamber and then fall down. After that, the falling materials with materials shot from the impeller form a continuous materials curtain. Ultimately, crushed materials will be charged from the discharging open.

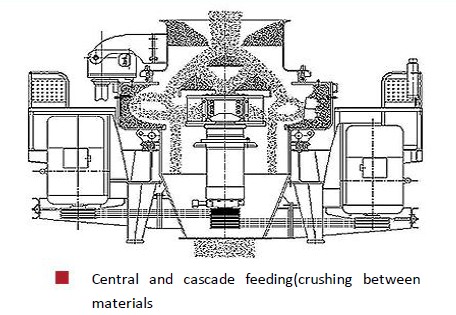

center feeding & ring feeding of vertical shaft impactor(VSI)

The materials fall into the hopper and the circle hole and then will be divided into two parts by the distributing plate. One part of materials cross the distributing plate and enter the high speed impeller and then is accelerated and thrown out. The other part falls down from the sides of distributor. Materials firstly strike the free falling down materials. Then, materials strike the materials-liner in the vortex or the impact liner and are rebounded to the top of crushing cavity and then fall down. The falling materials with materials shot from the impeller form a continuous curtain of materials. At last, crushed materials will be discharged from the discharging opening.

Technical Data of vertical shaft impactor(VSI)

| model | VSI5X7615 | VSI5X8522 | VSI5X9532 | VSI5X1145 | |

| Throughput capacity (t/h) | Center and Ring feeding | 150~280 | 240~380 | 350~540 | 500~640 |

| Center feeding | 70~140 | 120~200 | 180~280 | 250~360 | |

| Max. Feed Size (mm) | Soft material | <35 | <40 | <45 | <50 |

| Hard material | <30 | <35 | <40 | <45 | |

| Rotation speed (r/min) | 1700~1900 | 1500~1700 | 1300~1510 | 1100~1310 | |

| Power of double motor (KW) | 150 | 220 | 320 | 440 | |

| Overall dimension L x W x H (mm) | 4100×2330×2300 | 4140×2500×2700 | 4560×2600×2900 | 5000×2790×3320 | |

| Weight (t) | 8.6 | 11.8 | 17.5 | 27.5 | |

| Power source | 380v,50Hz | ||||

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;