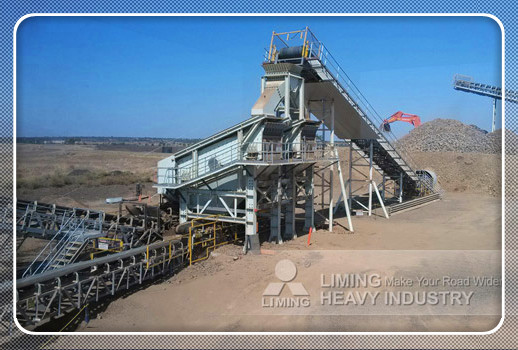

500TPH graphite production process introduction

Need graphite production line equipment: jaw crusher PEX series, HP series hydraulic cone crusher, mobile crusher, vertical mill, ball mill processing equipment and other auxiliary equipment.

Crushing section overview:

1, the mine materials after vibrating feeder feeding to jaw crusher for crushing, after crushing material of cone again broken role in meeting the requirements of the ball mill grinding feed particle size.

2, crushing material after a vibrating screen for screening out qualified granularity, granularity of qualified into the bunker, unqualified granularity via conveyor belt material to send broken again until after reaching qualified into the bin.

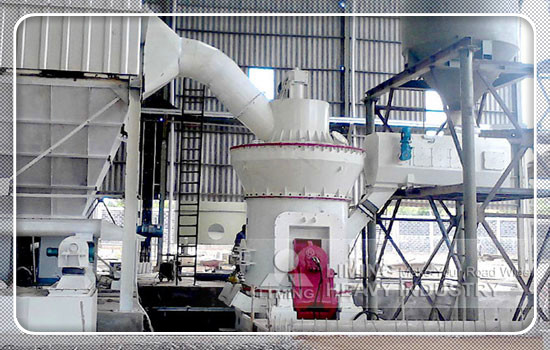

Two, the abrasive section and the flotation section

3, after grinding classification and the ore material for roughing, after rougher concentrate into the flotation machine selection, the scavenging concentrate into the flotation machine, scavenging concentrate into the pool, tailings into tailings pond.

After flotation, the concentrate is entered into the concentrate pool, and the tailings are in the scavenging machine.

5, concentrate pool through the concentrate slurry pump to high frequency to high frequency sieve sieve granularity into the mixing barrel and then through the lower flotation machine flotation, flotation concentrate into the lower pool, tailings pool will once again return to the superior concentrate into the flotation flotation machine to continue.

6, the fine ore that does not reach the qualified grain is entered into the ball mill to continue to grind, grind and then enter the high frequency sieve to pass the flotation machine flotation.

The above coarse selection passes through two high frequency sieving, four high fine grinding and the concentrate is made from the concentrator into the ceramic filter press, and then the dryer is dried.

The process of satisfying the product number of the finished ore by sifting through the line sieve.

New Energy Lithium Ore Mining Process

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;

Categories

- About Us (7)

- Accessory Equipment (356)

- Aggregate Crusher (724)

- Algeria Crusher (213)

- Angola Crusher (99)

- Argentina Crusher (54)

- Artificial Sand Crusher (88)

- Australia Crusher (78)

- Azerbaijan Crusher (33)

- Barite Crusher (76)

- Basalt Crusher (126)

- Bauxite Crusher (108)

- beneficiation plant (258)

- Bentonite Crusher (71)

- Bolivia Crusher (62)

- Brazil Crusher (103)

- Calcite Crusher (210)

- Calcium Carbonate Crusher (212)

- Canada Crusher (103)

- Cement Crusher (226)

- Chile Crusher (203)

- Coal Crusher (325)

- Colombia Crusher (100)

- Concrete Crusher (229)

- Construction Crusher (295)

- Copper Crusher (114)

- Crusher Advantages (102)

- Crusher Application (151)

- Crusher Maintenance (67)

- crusher operation manual (71)

- Crusher Technology (105)

- Crusher Type (109)

- Crushing Plant (389)

- Dolomite Crusher (65)

- Dubai Crusher (58)

- Egypt Crusher (87)

- Equipment Brand (167)

- Ethiopia Crusher (64)

- Exhibition (275)

- FAQ for Cone Crusher (179)

- Faq for Grinding Mill (505)

- FAQ For Vibrating Screen (17)

- FAQ Jaw Crusher (87)

- FAQ Spiral Classifier (11)

- Feldspar Crusher (47)

- Finland Crusher (42)

- Fly Ash Crusher (132)

- France Crusher (26)

- Germany Crusher (66)

- Ghana Crusher (54)

- Glass Crusher (11)

- Gold Ore Crusher (164)

- Granite Crusher (94)

- Gravel Crusher (128)

- Grinder Application (289)

- Grinding Plant (235)

- Grinding plant (325)

- Gypsum Crusher (116)

- India Crusher (117)

- Indonesia Crusher (90)

- Industrial News (58)

- Ireland Crusher (16)

- Iron Ore Crusher (143)

- Italian Crusher (30)

- Japan Crusher (19)

- Kaolin Crusher (36)

- Kazakhstan Crusher (37)

- Kenya Crusher (30)

- Korea Crusher (26)

- Liberia Crusher (39)

- Limestone Crusher (173)

- Malaysia Crusher (42)

- Marble Crusher (47)

- Material Mining Solutions (83)

- Materials Crusher (29)

- Metal Crusher (56)

- Mexico Crusher (23)

- Mongolia Crusher (32)

- Nepal Crusher (22)

- New Zealand Crusher (23)

- Nigeria Crusher (29)

- Oman Crusher (13)

- Pakistan Crusher (43)

- PDF (165)

- Pebble Crusher (57)

- Philippines Crusher (38)

- Poland Crusher (17)

- Product (65)

- Production Line (100)

- Project Case (68)

- Qatar Crusher (27)

- Quartz Crusher (44)

- Romania Crusher (17)

- Russia Crusher (26)

- Sand Crusher (133)

- Saudi Arabia Crusher (24)

- Scotland Crusher (7)

- Silica Sand Crusher (73)

- Singapore Crusher (6)

- Slag Crusher (70)

- Solutions (74)

- South Africa Crusher (52)

- Sri Lanka Crusher (13)

- Stone Crusher (119)

- Sweden Crusher (9)

- Talc Crusher (31)

- Tanzania Crusher (27)

- Thailand Crusher (16)

- Track-mounted Crusher (114)

- Turkey Crusher (17)

- UAE Crusher (11)

- UK Crusher (6)

- Uncategorized (13)

- United States Crusher (23)

- Used Crusher Equipment (29)

- Uzbekistan Crusher (18)

- Vietnam Crusher (28)

- Wall Putty Making Plant (64)

- Wheel-mounted Mobile Crusher (102)

- Zambia Crusher (45)

- Zimbabwe Crusher (41)

- Zircon Crusher (45)

Customer Distributed

- Algeria Crusher

- Argentina Crusher

- Australia Crusher

- Azerbaijan Crusher

- Brazil Crusher

- Chile Crusher

- Colombia Crusher

- Dubai Crusher

- Egypt Crusher

- Finland Crusher

- Germany Crusher

- Ghana Crusher

- India Crusher

- Indonesia Crusher

- Italy Crusher

- Japan Crusher

- Kazakhstan Crusher

- Kenya Crusher

- Korea Crusher

- Liberia Crusher

- Malaysia Crusher

- Mexico Crusher

- Mongolia Crusher

- Nepal Crusher

- Nigeria Crusher

- Oman Crusher

- Pakistan Crusher

- Philippines Crusher

- Poland Crusher

- Qatar Crusher

- Romania Crusher

- Russia Crusher

- Saudi Arabia Crusher

- Singapore Crusher

- South Africa Crusher

- Sri Lanka Crusher

- Sweden Crusher

- Tanzania Crusher

- Thailand Crusher

- Turkey Crusher

- UAE Crusher

- United States Crusher

- Uzbekistan Crusher

- Vietnam Crusher

- Zimbabwe Crusher

- Angola Crusher