Small impact mill is mainly used for primary and secondary crushing in the sectors of mining, ceramics, iron and steel industries, as well as environmental and recycling technology and the pit and quarry industry. It can crush limestone and gypsum rock, salt, various types of ash and slag, hard coal, overburden and similar materials.

small impact mill working flow

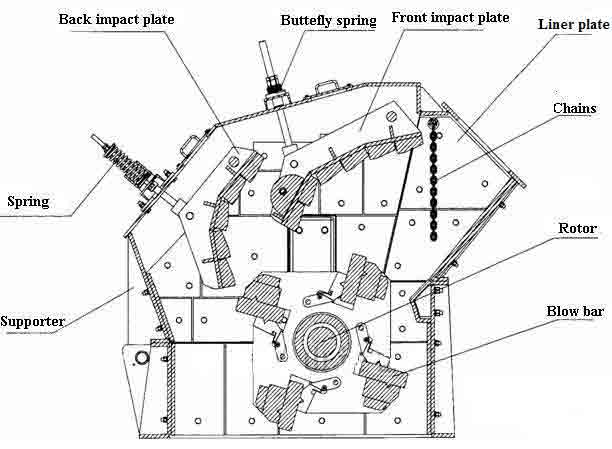

After entering the crushing radius of the rotor, the feeding material is grasped by the beater ledges, flung against the impact rockers and crushed by repeated impact stress. This produces a largely crack-free final grain with a high cubic proportion of grain. Final grain distribution can be influenced by the setting of the impact rockers towards the crushing radius of the rotor (gap widths) and by the speed of the rotor. The adjustment of the impact rockers is carried out by means of a worm drive mechanism. Compensation for wear of the beater ledges and the impact plates is granted due to the adjustment. In order to prevent possible damages caused by any foreign matters entering the machine, the impact rockers are spring-mounted, i.e. they can avoid any temporary overloads.

small impact mill manufacture

Liming is a leading crusher and mill manufacture in the world, and supply various model impact mill. Our impact mill has been proved that this series of crushers not only effectively increase productivity and final product quality, but also greatly reduce the investment costs and operation costs. It has export to many countries, and have a wide market. So if you want to know more information, please contact us, we will give you a detailed reply!

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;