Brief Introduction

YKN series vibrating screen, which is successfully developed on base of 30 years experience in designing of vibrating screen and combination with advanced international vibrating screen manufacturing technology, is high-efficiency vibrating screen of high strength and large vibration force.

YKN series vibrating screen adopts lumpish eccentric vibrator of N series. The intermediate transmission connection adopts flexible connection, which is of larger amplitude and more smooth vibration, thus it significantly increases the through capacity and screening efficiency of the vibrating screen and ensures the reliability and longevity of the equipment.

Performance Advantages

- Stable working

Connection between motor and vibrator adopts flexible coupling, which makes torque transmission have no axial force transfer and its working more stable.

- Optimized structure

Using the finite element analysis technology to optimally calculate the screen frame; side plate adopts the overall bending parts, on which welding crack is not easy to produce; through adjusting the eccentric block quantity, vibrator can meet the requirements of different exciting force and different amplitude.

- Easy maintenance

This vibrating screen series adopts synchronous cog belt structure, which is lighter in weight and easier in maintenance compared with the synchronous gear; vibrator adopts external type eccentric block structure, which is more convenient in installation and teardown than the eccentric shaft vibrator and more easier in maintenance; With the universal joint connection between vibrator, the installation is more flexible.

Scope of Application

Various kinds of ores and rocks, etc., with not more than 5% moisture content, big lumpiness and large bulk density are the optimum for screening. They are mainly used in the screening operation of building materials, mining, chemical industry, cement and other industrial departments.

Structure

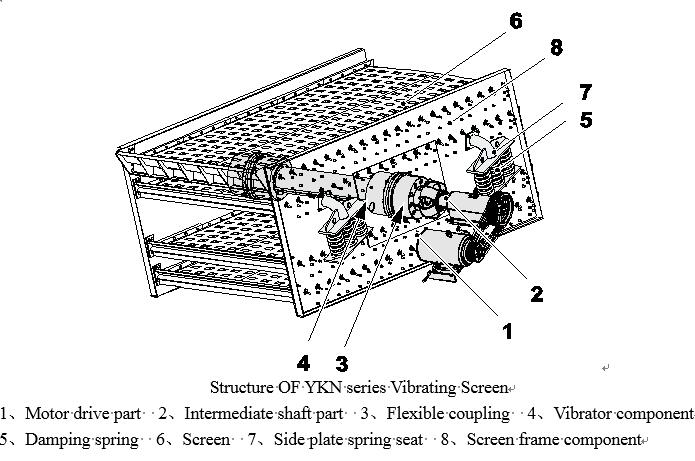

- YKN series circular vibrating screen mainly contains the motor drive part, intermediate shaft part, flexible coupling, vibrator component, screen frame component, etc.

- Intermediate shaft part is the center section for transmitting power. It includes driving wheel, intermediate shaft, overall bearing block, coupling plate, etc.

- Flexible coupling is mainly used to transfer power to the vibrator.

- Vibrator component is the power source for screening. It mainly includes eccentric block, deputy eccentric block, bearing, bearing block, short shaft, universal coupling, etc.

- Screen frame component is the direct carrier for accomplishing the screening operation. It mainly includes the stamping forming side panel, cross-brace, cross girder, screen mesh and its fixed parts.

Structure OF YKN series Vibrating Screen

1、Motor drive part 2、Intermediate shaft part 3、Flexible coupling 4、Vibrator component

5、Damping spring 6、Screen 7、Side plate spring seat 8、Screen frame component

Working Principle

YKN series circular vibrating screen is Single-quality system of forced vibration screening equipment composed of the vibration parts with the screen box and exciter, etc. and the spring as elastic component.

When working, the motor drives the exciter by the intermediate shaft and the flexible coupling to make the eccentric block of exciter rotating rapidly, and then generate the exciting force, which drives the screen box vibrating continuously. The material makes continuous projectile motion on tilted screen surface along with the screen box. When thrown up, the materials are layered, and in the process of fallen down to contact with the screen surface, the granules are falling through the sieve, the classification process of granule is completed again and again.

Technical Parameter:

| model | screen area

(m²) |

installation angle (°) |

sieve size

(mm) |

the Max. Screen size

(mm) |

number of vibration

(r/min) |

double amplitude(mm) | installed power(kW) | capacity(t/h) |

| 2YKN1860 | 2×10.8 | 20 | 5~150 | 400 | 800-900 | 5~9 | 22 | 70~400 |

| 3YKN1860 | 3×10.8 | 20 | 5~150 | 400 | 800-900 | 5~9 | 22 | 70~400 |

| 4YKN1860 | 4×10.8 | 20 | 5~150 | 400 | 800-900 | 5~9 | 30 | 70~400 |

| 2YKN2160 | 2×12.6 | 20 | 5~150 | 400 | 800-900 | 7~11 | 30 | 100~600 |

| 3YKN2160 | 3×12.6 | 20 | 5~150 | 400 | 800-900 | 7~11 | 37 | 100~600 |

| 4YKN2160 | 4×12.6 | 20 | 5~150 | 400 | 800-900 | 7~11 | 45 | 100~600 |

| 2YKN2460 | 2×14.4 | 20 | 5~150 | 400 | 800-900 | 7~11 | 30 | 150~850 |

| 3YKN2460 | 3×14.4 | 20 | 5~150 | 400 | 800-900 | 7~11 | 37 | 150~850 |

| 4YKN2460 | 4×14.4 | 20 | 5~150 | 400 | 800-900 | 7~11 | 45 | 150~850 |

| 2YKN3075 | 2×21.6 | 20 | 5~120 | 300 | 700-900 | 7~10 | 2×45 | 200~1200 |

| 3YKN3075 | 3×21.6 | 20 | 5~120 | 300 | 700-900 | 7~10 | 2×45 | 200~1200 |

| 2YKN3672 | 2×25.92 | 20 | 5~120 | 300 | 700-900 | 7~10 | 2×45 | 240~1650 |

| 3YKN3672 | 3×25.92 | 20 | 5~120 | 300 | 700~900 | 7~10 | 2×45 | 240~1650 |

Note: Any change of technical data shall not be advised additionally.

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;

Spodumene: According to the hard rock crushing process, the crushed product is generally 5-40mm, combined with different design requirements of customers, two-end or three-stage crushing, high-grade crushed products (above 4-5%) can be directly used in the metallurgical process to produce lithium carbonate Or lithium hydroxide, the particle size of the finished product is generally around 20-40mm; low-grade generally requires ball mill grinding and separation, and the particle size of the finished product is generally around 5-20mm;